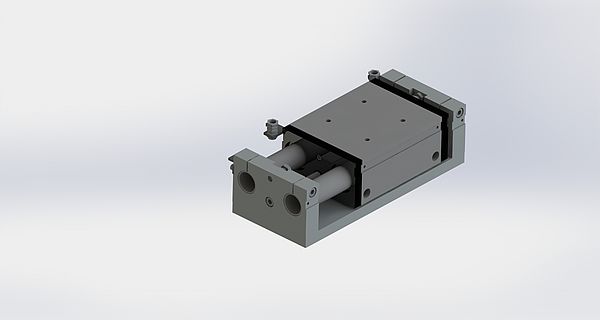

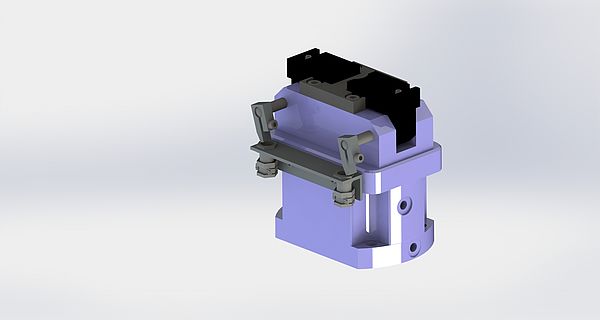

SHORT STROKE, PNEUMATIC

We offer a range of short-stroke modules for loading and unloading machines and for use in assembly areas. They are driven pneumatically via a cylinder with end position damping. This design ensures optimum speed and positioning accuracy.

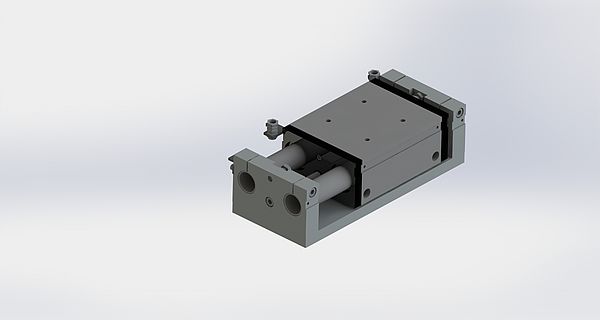

To product search >>SHORT STROKE, HYDRAULIC

We offer a range of short-stroke modules for loading and unloading machines and for use in assembly areas. They are driven hydraulically via a cylinder with end position damping. This design ensures optimum speed and positioning accuracy.

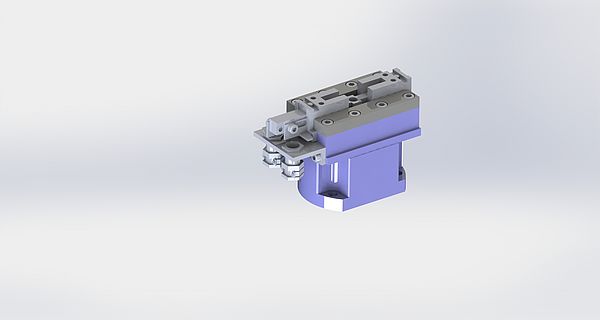

To product search >>PARALLEL GRIPPERS, PNEUMATIC, DIN/ISO FLANGE

FLT parallel grippers are sturdy clamping elements for workpieces or tools, and provide a secure hold during handling movements. The parallel movement of the jaws is generated by a pneumatic drive. In this version, they are available as DIN/ISO grippers with an intermediate flange.

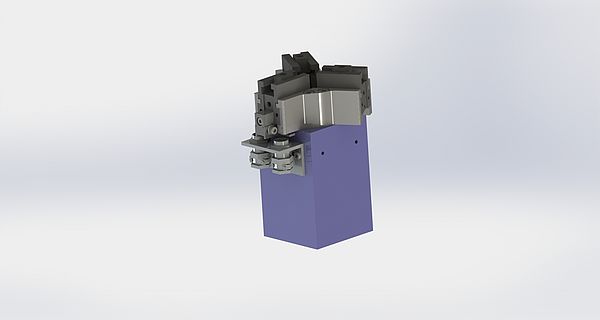

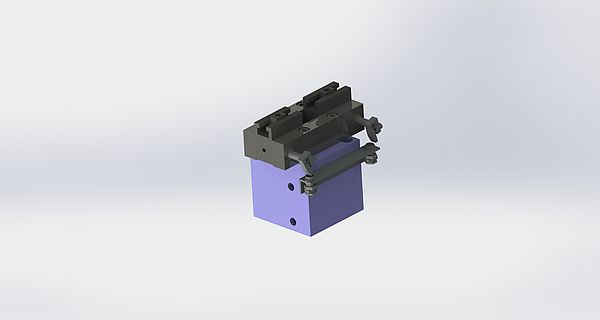

To product search >>PARALLEL GRIPPERS, PNEUMATIC

FLT parallel grippers are sturdy clamping elements for workpieces or tools, and provide a secure hold during handling movements. The parallel movement of the jaws is generated by a pneumatic drive.

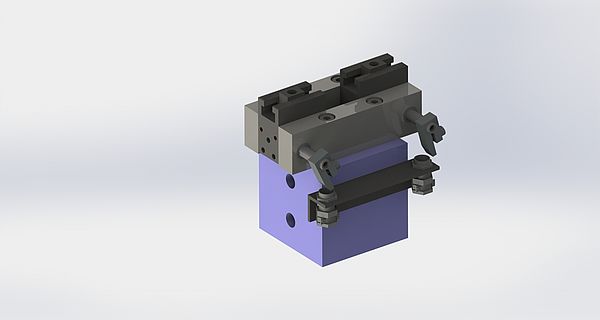

To product search >>PARALLEL GRIPPERS, HYDRAULIC

FLT parallel grippers are sturdy clamping elements for workpieces or tools, and provide a secure hold during handling movements. The parallel movement of the jaws is generated by a hydraulic drive.

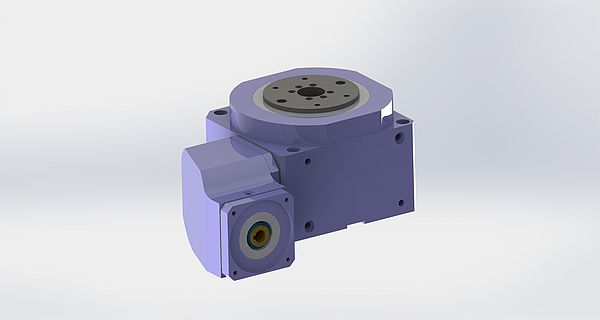

To product search >>ROTATION WITH ELECTRIC MOTOR

Our rotation modules with electric motors are highly versatile: they can be used as the rotation axis for a gripper head or as the base axis for a module combination, for example. They are driven by a three-phase servomotor.

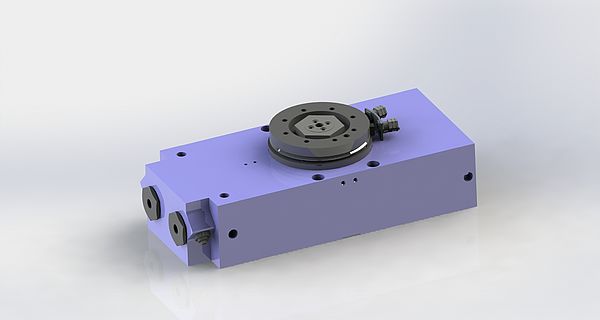

To product search >>ROTATION, PNEUMATIC

These powerful, compact modules from FLT are ideal for pneumatic applications. They are driven by a cylinder with end position damping. The nominal pressure is 6 bar. This design ensures optimum rotation speed and positioning accuracy.

To product search >>ROTATION, PNEUMATIC, WITH SHOCK ABSORBERS

These rotation modules for pneumatic applications feature an end position damping function that uses integrated, easily adjustable shock absorbers. The nominal pressure is 6 bar. This design ensures optimum rotation speed and positioning accuracy.

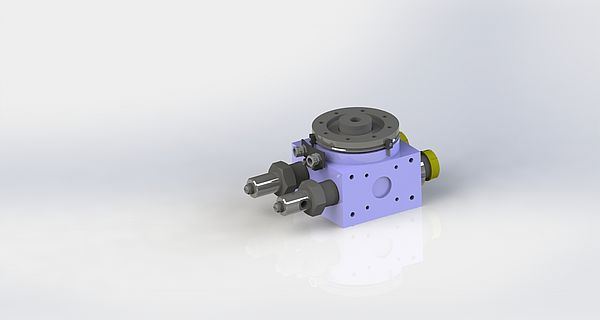

To product search >>ROTATION, HYDRAULIC

Our modules for hydraulic applications are available as versions with additional cylinders for the third and fourth positions, with rotation distributors and distributor plates, and in double-flange designs. They are driven by a cylinder with end position damping. The nominal pressure is 100 bar. This design ensures optimum rotation speed and positioning accuracy.

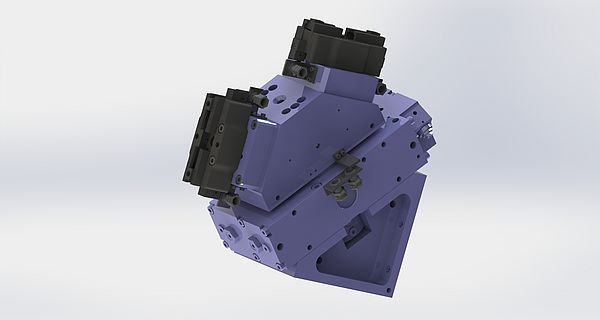

To product search >>PIVOTING TWIN GRIPPERS

Our pivoting twin grippers feature two integrated gripper modules in an angled configuration. They can be combined with equipment such as rotation modules with rotary unions, and provide a straightforward, compact solution for changing workpieces quickly.

To product search >>ANGLED GRIPPERS, PNEUMATIC, DIN/ISO FLANGE

Angled grippers for precise handling are particularly common in applications that involve changing workpiece sizes. Our cost-effective, compact gripper solutions are pneumatically driven and feature a DIN/ISO flange for direct installation on robots or handling devices.

To product search >>ANGLED GRIPPERS, PNEUMATIC

Angled grippers for precise handling are particularly common in applications that involve changing workpiece sizes. Our cost-effective, compact gripper solutions are pneumatically driven.

To product search >>ANGLED GRIPPERS, HYDRAULIC

Angled grippers for precise handling are particularly common in applications that involve changing workpiece sizes. Our cost-effective, compact gripper solutions are hydraulically driven.

To product search >>