THE 2022 FISCAL YEAR

LÄPPLE Group was again faced with major challenges in 2022 due to many geopolitical as well as economic global developments. The Group nevertheless closed the fiscal year on a satisfactory note.

After a positive start to the year, primarily due to good volumes in the automotive business, the rest of the year was strongly influenced by external factors. The rotary tables business unit was particularly affected by the global material and supply bottlenecks. Project delays and reluctance to place orders were felt in the areas of standard parts and automation. In the automotive sector, it was necessary to respond flexibly to fluctuating order volumes throughout the year.

New orders were also won in the growing e-mobility market in 2022. The companies of the LÄPPLE Group continue to keep pace with the technological changes in the industry with considerable expertise with regard to the changes in production complexity. New projects include a series order for the production of a battery housing cover. The expansion of the product portfolio to include powertrain parts illustrates the company's evolution into a systems supplier in the automotive sector.

Digitalization continues to be the focus of all business areas. Involvement in development projects in the field of automation, the expansion of e-commerce activities for standard parts and the expansion of the training center's retraining program with a focus on IT were important projects in this respect in 2022.

In the traditional market of sheet metal processing, LÄPPLE AUTOMOTIVE has succeeded in a highly innovative development. The patented MFD (Multi-Functional Die) tool concept makes it possible to reduce the number of operations in sheet metal part production from six to just one. This not only results in considerably lower investment and production costs, but also in a significant improvement in the environmental balance. In 2022, an initial customer project using the new technology was approved and is currently in process.

CURRENT SITUATION AND OUTLOOK

"We assess the developments of the current business year as difficult to foresee due to the geopolitical uncertainties," says Stephan Itter, Spokesman of the Management Board of LÄPPLE AG. "Regardless, we are focused on our long-term goals and are committed to strengthening our agility and resilience. We are working on this in an active and well-disciplined manner, which is why we are confident about the medium- and long-term development of our group of companies."

LÄPPLE AUTOMOTIVE continues to show crisis stability and continues its growth strategy as a system supplier in automotive module production. While the transformation of the company is at an advanced stage in Heilbronn, the separation of the series and aftermarket businesses at the Teublitz site will have to be further advanced in 2023 in order to make the business units there more competitive as well.

In addition to the sale of standard parts, FIBRO Standard Parts is also positioning itself as a system provider in toolmaking and is increasingly offering additional services, such as logistics, as a complete solution for customers. With a new sales structure and the associated closer alignment to the market and customers, the Standard Parts business unit plans to expand its global activities in 2023.

FIBRO Rotary Tables needs to place the new products in the still weak mechanical engineering market. In addition, the supply chains must be further strengthened, and the speed of customer processing and delivery must be increased and improved.

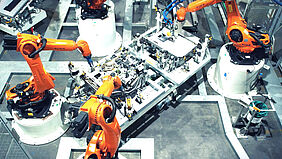

As a 360-degree provider in the automation market, FLT focuses on the growing e-mobility market. High levels of expertise in virtual engineering support customers in optimizing their production and making it more flexible. Through research projects such as with the Darmstadt University of Applied Sciences or the Karlsruhe KIT, FLT is constantly expanding its automation expertise.

At LÄPPLE AUS- UND WEITERBILDUNG, the next generation is trained to meet the growing demands of our companies (37 trainees & students in 2023). Business administration and IT were particularly popular choices when it came to retraining and further education in 2022, while there was a noticeable decline in the technical field.

SUSTAINABILITY MANAGEMENT

As part of its company-wide sustainability management, LÄPPLE consistently works on key topics such as effective supply chains, climate and environmental protection, and sustainable energy generation and use.

The installation of a large-scale photovoltaic system at the Heilbronn site, the switch to LED lamps in all production areas, the optimization of recycling management, and an energy-saving campaign are just some of the measures that are making an important contribution towards decarbonizing the Group.

ABOUT THE LÄPPLE GROUP

The LÄPPLE Group is a globally active, independent supplier of pressed parts, body modules, standard parts, and rotary tables, as well as automation solutions. Innovative product development, state-of-the-art technologies and the passion of around 2,400 employees – for over 100 years, the name LÄPPLE has been synonymous with quality and reliability. A unique, practically oriented education and further training program offered by the certified professional training company LÄPPLE AUS- UNd WEITERBILDUNG guarantees this performance in the future as well.

LÄPPLE AUTOMOTIVE is a specialist for sheet metal and forming solutions in the field of car body construction for international premium suppliers to the automotive industry. As a system partner for forming and stamping tools, FIBRO Standard Parts offers process optimization services for the global toolmaking market in addition to numerous product innovations. FIBRO Rotary Tables carries a wide range of products with various models of rotary tables for the machine tool market and the automation industry. At FIBRO LÄPPLE TECHNOLOGY (FLT), the Group bundles its expertise in the automation sector. FLT develops, produces and installs intelligent automation solutions for customers worldwide.